New powder material Nano-sized Zeolite Zeoal

![]()

Realized practical-level production cost

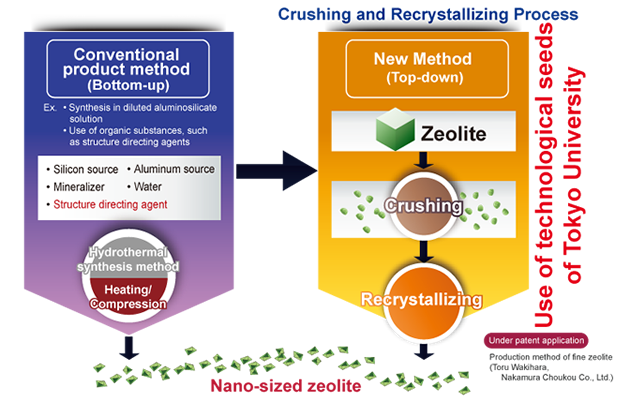

Nakamura Choukou Co., Ltd., in collaboration with Tokyo University, developed an innovative production process for zeolite nano-particles by utilizing the crushing and recrystallizing technology held by the University, and succeeded in production of low-cost nano-sized zeolite powder.

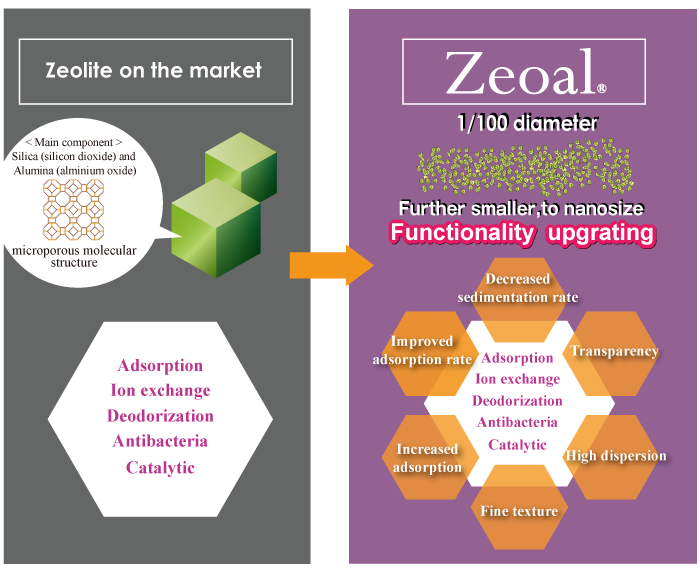

While maintaining zeolite’s inherent functions such as adsorption, this technology allows to minimize the particle size to 50 - 300 nm.

By minimizing the particle size to an unnoticeable level by human five senses, this technology does not damage the basic properties and esthetics of the target objects to which the function is added. The technology opens the door to possibilities widely, for example, optical application which requires light transparency, and addition to tiny fibers.

Expected influence of nano-sizing

Zeolite is composed of mainly silica (silicon dioxide) and alumina (aluminum oxide), and characterized by a microporous molecular structure, and has a large surface area equivalent to over one tennis court per gram.Because of this property, zeolite possesses the functions of “adsorption,” “ion exchange,” and “catalyst,” and is used broadly in the chemical field, as a catalyst for purifying the exhaust gas from automobiles; in the environmental field, as an adsorbent for radioactive cesium; and in the daily-life field, as an antibacterial agent for masks, and others. Micron-size particles are currently distributed, but when the particle size reaches the nano level, the above basic functions will improve drastically, and they will be used for new purposes.

However, the conventional method for producing nano-sized particles takes a lot of cost, and so concrete market evaluation has not progressed.

In these circumstances, Nakamura Choukou commenced the development of an innovative process for producing nano-sized zeolite by utilizing the nano-technology nurtured by the Company for many years in parallel with the life science business and the “Crushing and Recrystallizing Process” technology owned by Tokyo University, and then succeeded in producing “nano-sized zeolite,” whose particle size is one millionth of ordinary zeolite, at low cost.

(This “Crushing and Recrystallizing Process” is patent-pending.)

D-Next Business

High-precision Equipment Business

Chemical Fiber Spinning Nozzle Business

About New Business

Others