With the high-precision processing of hard and brittle materials as a foundation, we manufacture long-lasting, high wear-resistant parts that use high-hardness materials such as sintered diamond (PCD), cemented carbide, and ceramics.

We specialize in the ultra-precision processing of high-hardness materials in microns, with our core technologies in the special manufacturing areas of brazing technology, heat processing technology, electrical machining technology, grinding processing technology, etc.

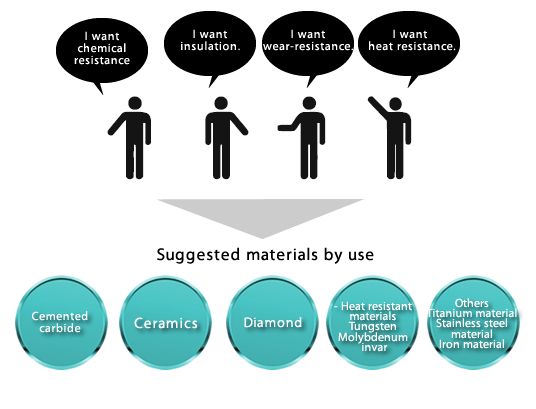

Suggesting materials according to use

Our parts come in many shapes and sizes for a variety of uses, with unique traits for use in different environments.

And we can suggest the ideal parts to meet specific customer demands, such as extra wear-resistance.

Our suggestions are very accurate, regardless of which materials are used.

Micro and Precision Processing, Pushing the Specs for High-Hardness Materials to the limit

Sintered diamond |

We take advantage of sintered diamond's reputation as the hardest substance on earth, along with its remarkable heat conductivity, and apply it to super wear-resistant parts, thermal compression tools, etc. At Nakamura Choukou, we primarily use sintered diamond when performing electro discharge processing or grinding for high-precision finishing. |

|---|---|

Cemented carbide |

The steady wear-resistance and flexibility of cemented carbide make it an efficient material for use in a wide range of tools and parts. |

Ceramics |

Ceramics not only provide remarkable wear-resistance, but are also light-weight, resistant against heat and corrosion, and offer remarkable electrical properties. Ceramics are joined and sprayed onto shaft bearings and seals, super finishing machine work rests, and transport device parts that require solid insulation performance, and high-precision grinding is also made possible. |

Processing Methods

Electro-discharge Processing

Sodick“AP200L” |

【Wire electro-discharge processing】 Electrode wires are used to perform ultra-precision shape processing of super-hard materials. Moreover, by inclining the wires, tapering and coaxial processing can also be performed. 【Die sinking electro-discharge processing】 Electrode materials are processed into various shapes, and the shapes are transferred to super-hard materials (die sinking). Wire electro-dischargers and super-fast, ultra-precise machining centers are used to manufacture electrodes. 【Micro-hole electro-discharge processing】 Pipe electrodes are used to process holes. Multiple holes can be processed. |

Grinding  Sodick High-Tech“MC430L” |

Includes general-purpose machines, NC milling machines, and the latest machining centers. For processing hard-to-cut materials, such as stainless steel, invar, and heavy metals. |

Flat surface processing  Nagase Integrex "SGC-94BL2D" |

Flat, smoothing processing is performed for super-hard materials, tempered steel, and stainless materials such as sintered diamond and cemented carbide, via grinding wheels for reciprocation. |

Cylindrical grinding  JTEKT“GUP32-50(100)” |

Grinding wheels are used to perform the cylindrical grinding process. Our main tool is an all-purpose grinding machine which can perform inner and outer grinding. We can grind the outer diameter and edge surfaces by supporting at both centers, and machine the inner and outer diameters with one chuck using an open side with the chuck. This can be used for processing of super-hard materials and tempered steel, such as sintered diamond (PCD), cemented carbide, etc. With our independently-manufactured jigs, we can also grind intermittent circular arcs. |

Grinding tools |

We support flat surfaces, cylindrical surfaces, chamfering and R, SR processing using our cup-type grinding wheel. Our facilities feature multiple axes, where we perform R and SR (hemisphere face) processing that cannot be expressed in regular flat or cylindrical form, for super-hard materials such as sintered diamond (PCD) and cemented carbide. |

Joining |

In order to add wear-resistance and other features locally, for necessary parts only, we join hard materials with iron materials, etc. |

D-Next Business

High-precision Equipment Business

Chemical Fiber Spinning Nozzle Business

About New Business

Others