We are independently developing, manufacturing, and distributing "DINA-PRISM," a diamond wire cutting tool that is essential to the slicing process of electronic materials used for solar batteries, LEDs, etc.

By using a unique fixed method for our diamond grains, we can achieve high-speed results, remarkable strength, and reduce costs, while maintaining a high reputation.

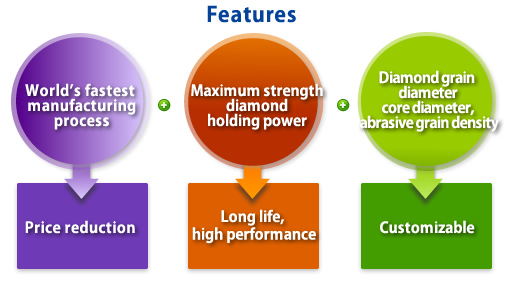

Features of our independently-developed "DINA-PRISM" Diamond Wire

What is Diamond wire?

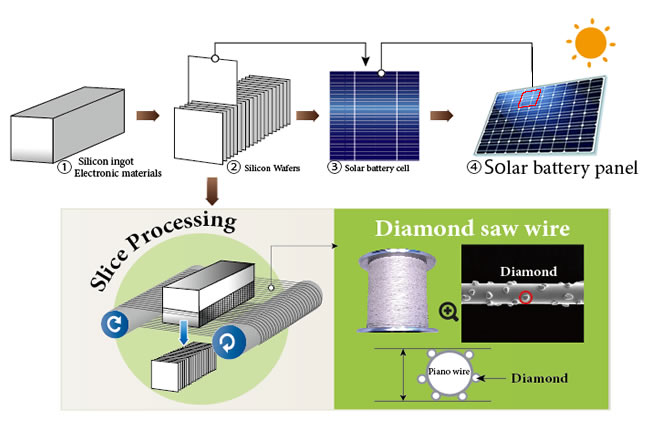

Manufacturing Process of Silicon Wafer

Nakamura Choukou's diamond wire is used in the slicing process in manufacturing silicon wafers, which are used for the main part of a solar battery panel, that is, a solar cell. A “diamond wire” is a tool used to thinly slice rectangular silicon ingots that are pre-cut to the dimensions of each wafer. It is a threadlike slicing tool made with a thin piano wire with diamond granules firmly attached and is thinner than a human hair.

Characteristics and strengths

Solutions for our clients

Our high-speed, high-strength diamond fixation technology enables us to produce our "DINA-PRISM" Diamond Wire with high-efficiency at a low cost.

This also allows us to provide speedy, detailed customization to meet the demands of various customers at the slice processing site.

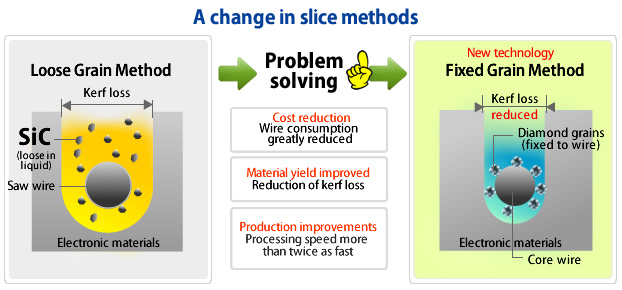

Transition from free abrasive grain method to fixed abrasive grain method

For the slice processing method used for electronic materials, we expedite transition from a conventional free abrasive grain method to a fixed abrasive grain method. The fixed abrasive grain method enables higher production capacity and eases environmental strain for a revolutionary improvement in slice processing of electronic materials.

Additionally, Nakamura Choukou is making efforts to further thin the diamond wire since increasing the number of silicon wafers produced from an ingot is an important advantage for wafer manufacturers in terms of production efficiency and cost reduction.

The 4th Japan Grand Prize METI Minister’s award

Diamond Wire Development Points

D-Next Business

High-precision Equipment Business

Chemical Fiber Spinning Nozzle Business

About New Business

Others